- Size Range : 15mm- 1500mm (1/2”- 60”)

- Ratings : As described in the relevant standard including ASME B16.5, ASME B16.47, EN1092, AS2129, AS/NZ 4087, API Spec 6A

- Sealing Type: Flat Face, Raised Face, Ring Joint

- Sealing Finish: Spiral Finish 3.2µm-12.0µm

- Materials: A105, A350LF2,LF3,LF6, A694 F42-F70, AS/NZS3678 Gr250 304,316, 2205 (A182 F51), 2207, Incoloy 625 or as requested

- Custom items: Our time frame for delivery is usually 10-20 days.

- Varieties: Weld Necks, Blinds, Slip-ons, Socket Welds, Lapped, Long Weld Necks. Please refer to visualise types under technical references to identify these types.

Flange is a generic description used to describe a device that terminates a pipe or device and provides a boltable joint. The concept is generic but the application is specific. Flanges are predesigned to meet process conditions. Standards exist that provide standardised dimensions and material types.

Flange Types: Weld Neck, Slip-on, Blind

Typical flange types are as follows:

Slip-on Weld (SOW): This flange is slipped over the pipe and a bead of weld placed around the inside at the sealing face and the outside at the neck.

Weld Neck (WN): Attached with a full penetration butt weld to the pipe. Very common in ASME B16.5 and sometimes called an ASME Weld Neck or ANSI Weld Neck.

Blind: Terminates the line.

Other types of flanges include: Long Weld Neck, Bossed Blind, Lapped Flanges, Stub Ends, Socket Weld and Screwed. Typical sealing variations include Raised Face, Flat Face and Ring Joint. Different industries tend to be dominated by different standards and the following chart illustrates the industries where the standards are used.

| AS2129 | Australian Standard | Flanges for piping valves & fittings A common industrial flange in Australia. Sold mostly with a spiral finish on a flat face. Used for water movement and general industrial fluids, including in the food and wine industry. |

| AS4087 | Australian and New Zealand Standard | Metallic flanges for waterworks purposes Used generally for water supply projects such as government sponsored projects. Similar hole spacings to some AS2129 flanges. |

| ASME B16.5 | American Society of Mechanical Engineers | Pipe flanges & flanged fittings This is the mainstay for most heavy industrial and petrochemical plants. Covers flanges up to 600mm typically supplied with a raised face and spiral finish. |

| ASME B16.47 | American Society of Mechanical Engineers |

Large diameter steel flanges Found mostly in heavy industrial and petrochemical applications. Covers flanges above 600mm typically supplied with a raised face and spiral finish. Available in A and B type. |

| BSEN 1092-1 | British Industrial Flanges | Flanges & their joints Found on DIN pumps and other equipment from Europe and the UK. NB similar BS4504. |

| JIS B2220 | Japanese Industrial Standard | Steel pipe flanges These are seen mostly in Australia in ships. |

| ASME B16.36 | American National Standard |

Orifice Flanges These flanges are designed to sit either side of orifice plates for measuring flow. They will typically be supplied with a side port and jacking bolts. |

| ASME B16.48 | American National Standard | Line Blanks Spectacle Blinds, Fig 8 Blinds, Spades, Paddle Blinds, Spacers. |

| MSS SP-44 | American Manufacturing Standardisation Society | Steel Pipeline Flanges Similar ASME B16.47A. |

| AWWA C207 | American Water Works Association | Steel Pipe Flanges for Waterworks Some flanges have similar hole spacing to ASME B16.47A. |

| API 605 | American Petroleum Institute | Large Diameter Carbon Steel Flanges Similar ASME B16.47B. |

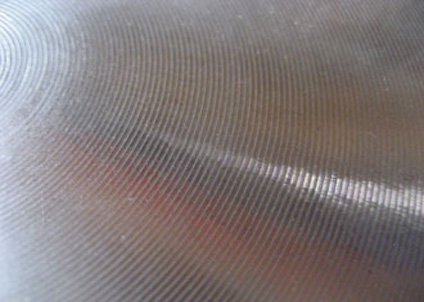

FLANGES SEALING FINISHES

Typically Weld Necks, Slip-ons and Blinds are produced as a raised face, flat face, or ring joint sealing surface depending on the application requirement. The spiral sealing face is a specified finish typically Ra 3.2um-6.3um.

Australian and New Zealand flange standards specify coarser sealing faces which are typically Ra 6.4um-12um.

FLANGES - MATERIALS

As an Australian manufacturer, Balcombe Engineering are able to manufacture the spectacle blinds in a material with the testing as required by the client specification. Typically, flanges will be manufactured from carbon or stainless steels. Typical carbon steel materials are AS1548 460NR, A516 Gr70 or forgings like A105, A350 LF2, A350 LF3. In corrosion resistant materials A240 P316L, A240 P304L, UNS31803 and A182 F316L, A182 F304L are common. Less common but easily supplied are Super Duplex 2207 and Incoloy 625.

Additionally, specialist finishes are available, for example - galvanising, PTFE coatings and linings and various epoxy finishes.

FLANGES - Corrosion Protection and Packaging

Each flange will always have a sealing face that requires protection. Weld Necks have an additional weld preparation that also requires protection. Whether you want the flanges preserved for 2 weeks or 2 years, Balcombe Engineering have a packing system that ensures that your Weld Neck, Slip-on and Blinds arrive at the installation in good condition. Our sales team are happy to provide additional information if more robust corrosion protection is required.

FLANGES SPECIAL

This photo shows the early machining

of a self-reinforced Weld Neck from

A182 F51 duplex material.

Sometimes a specific engineering requirement may dictate the need for special material and construction type that is required to produce the Weld Neck , Slip-on or Blind flange. Balcombe Engineering are a manufacturer with full ISO 9001 certification and are able to produce to your requirements including detailed testing and documentation.

All material is traced through the Balcombe Engineering system and ITPs and MDRs are available on request. Your order can be packaged in line with your engineering or project specifications and we are set up to complete the tasks within remarkably short delivery time frames.